Each egg tray making machine production steps from raw material purchase, metal parts manufacturing, egg tray machine assemble are inspected by professional quality inspector.

01Project pre-analysis, producing of paper egg tray making machine, installation of egg box tray machine, one-stop service.

02All technical questions about our egg tray making machine will be replied timely online, reliable spare parts supply with cost price.

03FEATURED PRODUCT

1. Siemens energy saving drive motor, low power consumption

2. High precision divider gearbox from Taiwan, International brand bearing

3. 4/8/12 sides auto rotary drum design, 2000-7000 pieces per hour capacities are available

4. Sunshine drying, brick drying oven drying, multi-layer metal dryer all are optional as requires

Enhanced molding machine frame

INVT brand inverter speed controller

10-20 drops per minute working speed

Aluminum or plastic material

Install max 7.5cm height molds

Quick to change forming molds

Three layers insulation design

Module design easy to assemble

Double-sided observation doors

| Model | GB500 | GB1000 |

| Mold template | 500*1200mm (customized) | 800*1000mm(customized) |

| Forming station | 1 | 2 |

| Working speed | 5-8 cycles/minute | |

| Working power | 55-75KW | 65-90KW |

Quick change forming molds

PLC control reciprocating molding

Install max 35cm height industrial tray molds

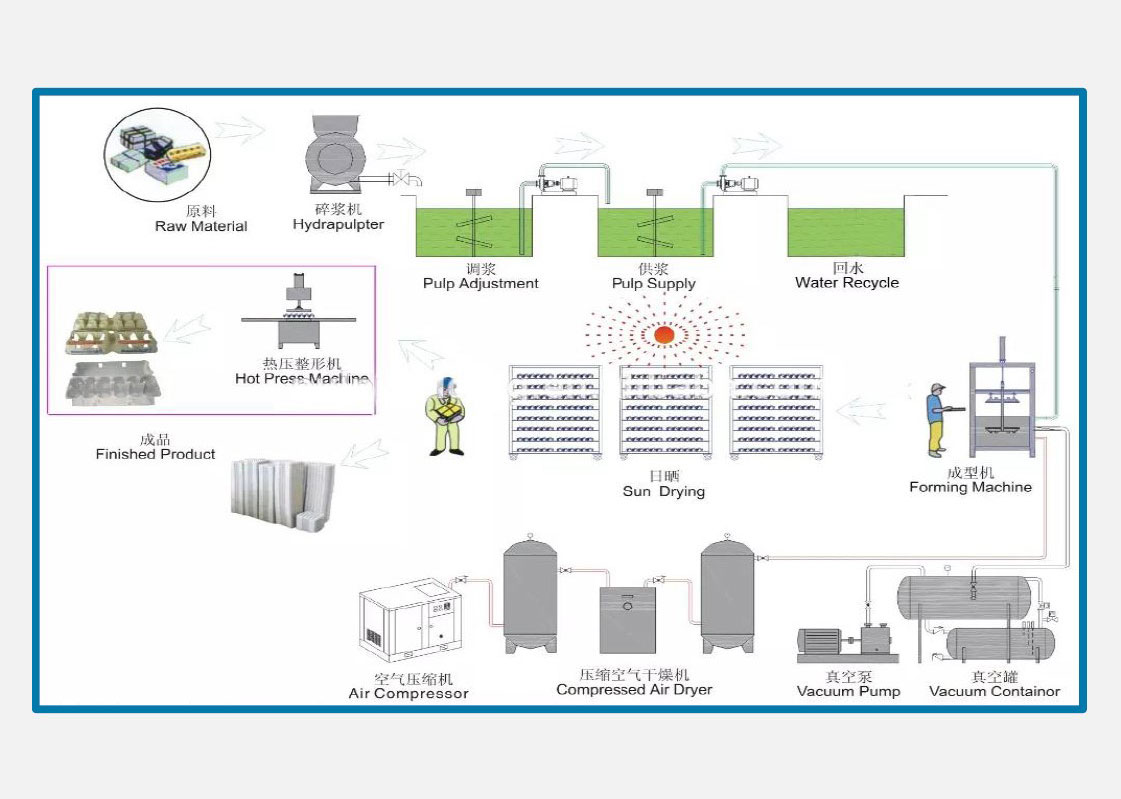

Waste paper recycling-Paper pulp molding-Sunshine or metal dryer drying-Hot press trimming-Storage

Can use the machine to make egg box tray wine bottle packing tray shoe tray fruit vegetable packing basket medical kidney tray etc

| Model | F1000 | F1500 |

| Capacity | 800-1000 Pcs/H | 1200-1500 Pcs/Hour |

| Molds Qty | 3 PCS | 4 PCS |

| Power consumption | 33KW | 42KW |

| Water consumption | 200kgs/h | 280kgs/h |

| Waste paper consumption | 70kgs/h | 105kgs/h |

Low investment, easy to install and operate, small covering area, best choice for small home business

Recycling waste paper OCC into egg box tray shoe support tray, popular in India

For small capacity egg box trays production usually use sunshine drying or multi-layer metal dryer

Since 2001, more than 20 years production history for paper pulp egg tray molding machines production, we are a high-tech enterprise that designs, produces and sells paper making machinery and pulping equipment. Mainly produces various types of egg tray making machines, carton box making machines other paper product making machines.

In China market, our egg tray making machines occupy more than 55% market, tissue paper machine and craft paper machines 35% domestic market; For abroad market, our paper pulp molding machines already been exported to more than 75 countries mainly in Africa, Asia, Middle East, South America and East Europe like Russia India Turkey Spain Egypt Saudi Arabia Philippine Malaysia Indonesia Uganda Venezuela Mexico Pakistan Yemen Morocco Nigeria Kenya

Strong production capacity and reliable technical support team, more than 45000 square meters production workshop, 4 sets advanced CNC parts manufacturing machines and 2 sets laser metal cutting machines, more than 150 skilled workers, 19 develop engineers, 28 after sales engineers for installation from China, India, Egypt.

Super class after-sales service, all of after sales installation service engineers are with rich of domestic and abroad installation experience, they will provide you the most professional installation and training service.

years, Production history

million USD, Sales Amount

Engineers, Professional

countries, Worldwide

OUR FACTORY

WE ARE CERTIFIED

Production

Argentina F2500

India A5500B

India A6000B

India FI1000

Indonesia A6000B

Iraq A4000M

Mali A2500M

Pakistan A6000B

Uganda A6000B

Ukraine A4000M

Venezuela A4000M

Client Production Site

PFK F1500 Small egg tray making machine

PFK GB Industrial paper pulp packing tray production

PFK A7000 pieces per hour egg tray production line

Clients around

PRODUCT INQUIRY

Contact us for more information about machine and we have many successful cases waiting for you.